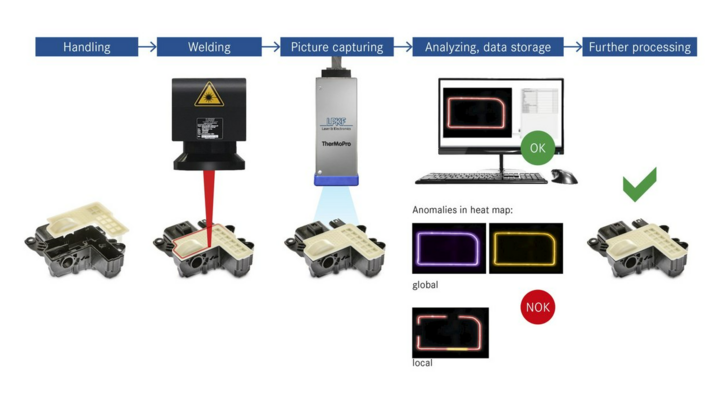

LPKF Software Solution, including

- PLC communication for trigger and traceability

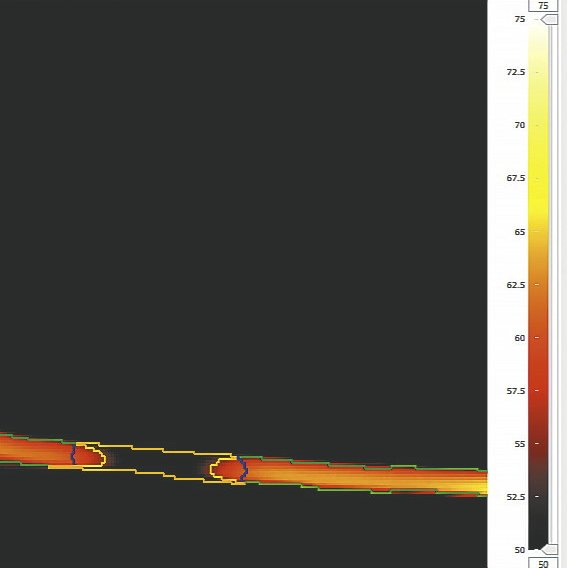

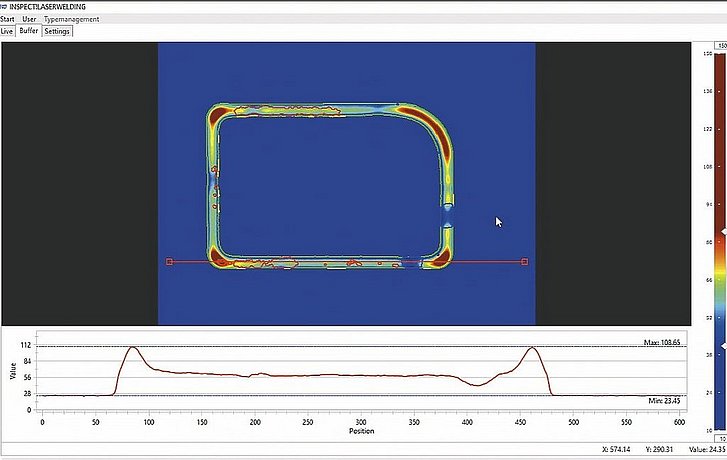

- Automated Contour-finding and statistical analysis

- Export of Results (pictures, data) for each part

- OK / NOK Decision according to type-specified criteria

- Additional functionalities for analyzing particular areas of the heat map

Why Choose an LPKF System?

- LPKF has extensive application experience in laser plastic welding, thermography systems and software solutions

- Strong collaboration between industrial partners in the context of R&D work

- The right way to analyze the data to get a reliable solution – to avoid false positives or false negatives

Downloads

Brochure

LPKF_TherMoPro_Camera.pdf (pdf - 319 KB)

![[Translate to USA:] TherMoPro [Translate to USA:] TherMoPro](/fileadmin/mediafiles/user_upload/products/TherMoPro/TherMoPro_schraeg.png)