Flexible process evaluation for optimum efficiency

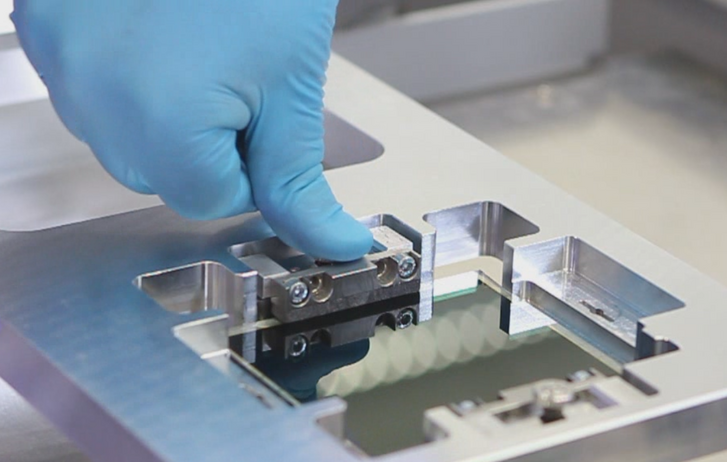

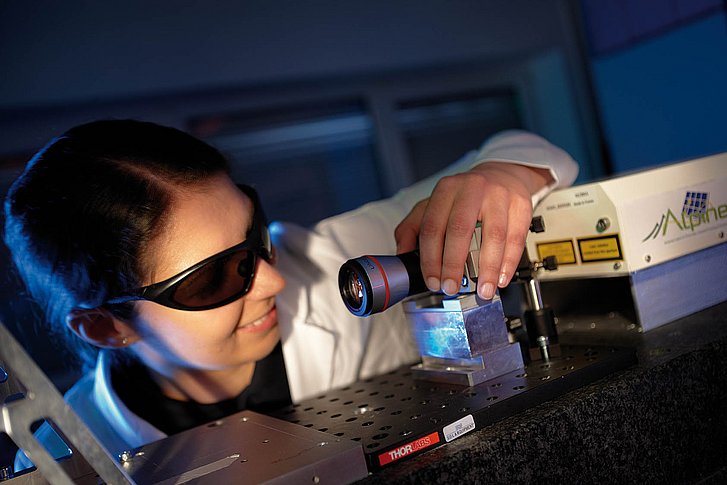

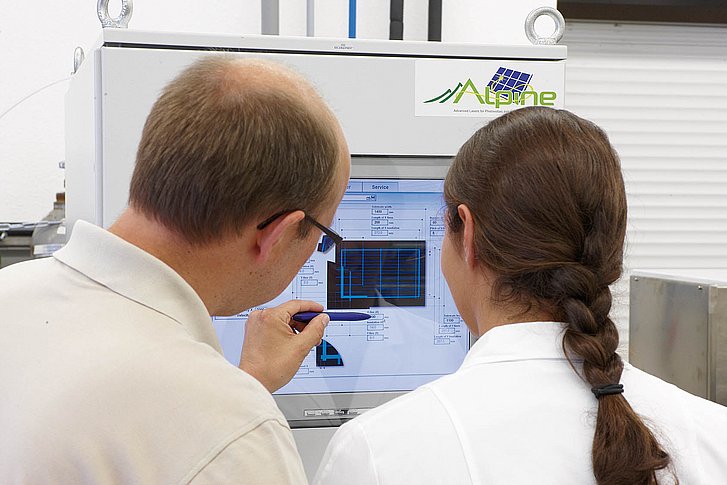

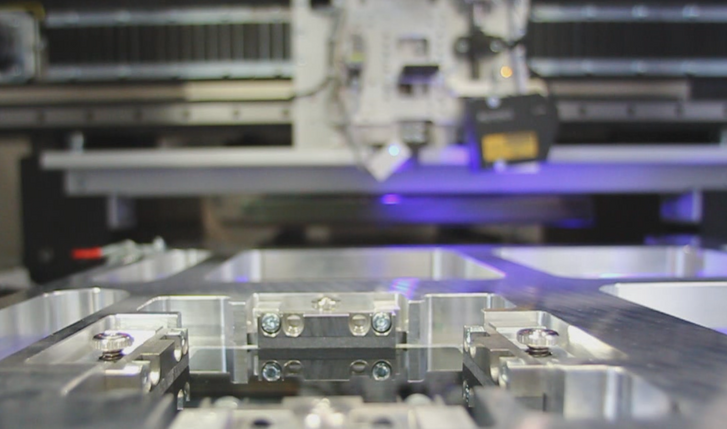

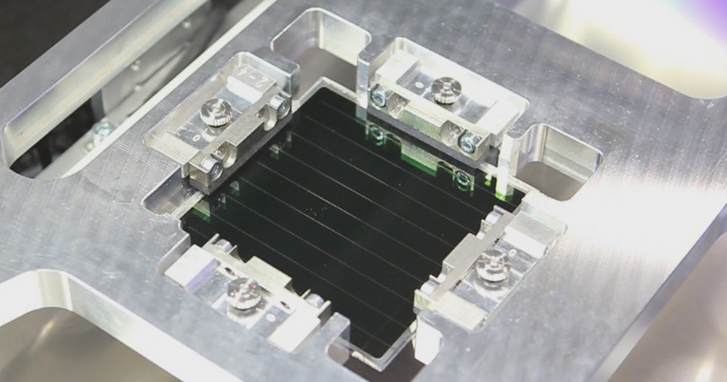

One main advantage is that the system can be equipped with various laser sources and a mechanical needle. It has been developed to handle all steps in laser structuring for thin film substrates: scribing the pattern in P1, P2 and P3. The special design allows both scribing of the coated side as well as through the glass substrate. An imagaing system is integrated to reference the P1 pattern to the P2 and P3 scribing steps.

Typical applications for LPKF Presto

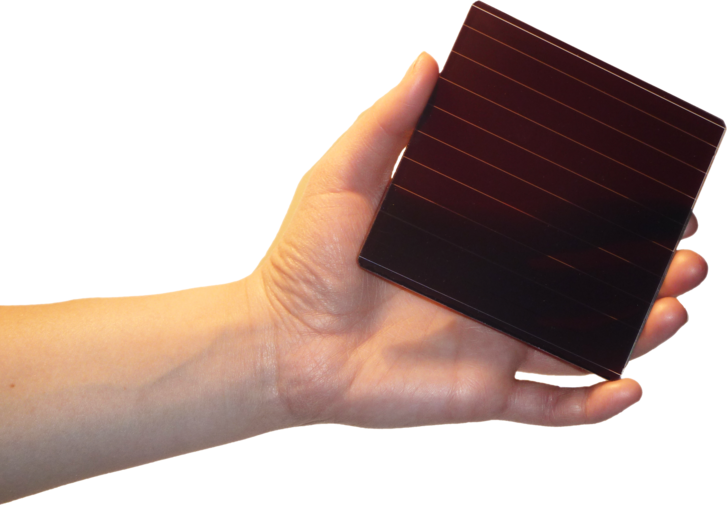

The Presto lab scriber serves different laboratories or start-up companies to scale up their thin-film lab cells to small modules with interconnected single cells. The size of up to 30cm x 30cm has proven to be large enough to qualify cell technology to be able to transfer the results into a production line. As laser source developments go forward in the direction of shorter pulses at shorter wavelengths, the Presto with its flexibility to integrate different lasers and to easily change the optical path will stay an important tool for thin-film companies. It enables them to carry out feasibility studies and qualify their technology for production.