Stencils in PCB Production

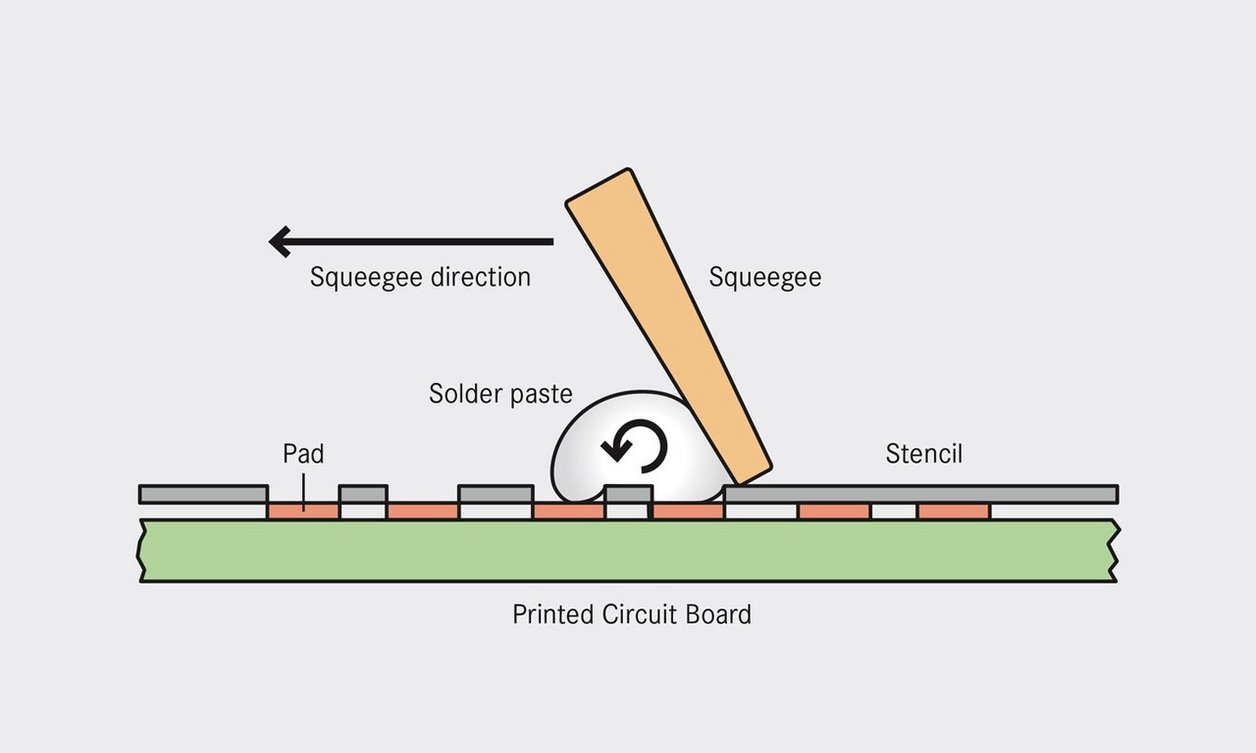

Stainless steel stencils play a central role in the SMT (surface mounted device) production process, as they are used to distribute the solder paste or adhesive on the PCB substrate and prepare it for subsequent assembly. The adhesive or solder paste is passed over the stencil with a squeegee and applied to the substrate through apertures in the stencil.

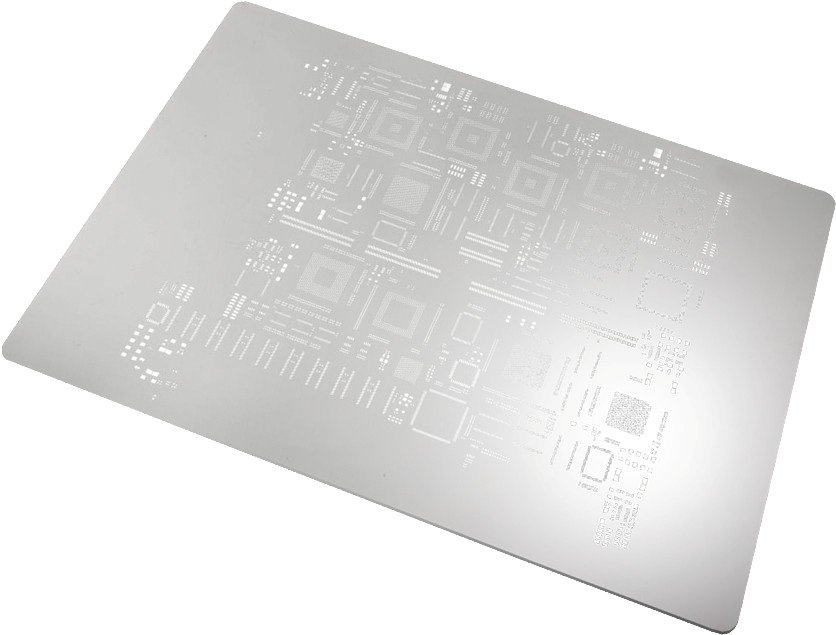

The quality and accuracy of the stencil is therefore of the utmost relevance in order to ensure that the PCB is manufactured with the least possible errors.

How the stencil manufacturing with laser works

For laser cutting of the stencils, the frames are fixated in the system and then the material is processed. For this purpose, the laser punches into the center of the area intedned for the respective aperature and then cuts the corresponding contours. The laser melts the material locally during processing and a cutting gas forces it out of the channel. Since the melt is not vaporized in this case, impressive cutting speeds can be achieved.

Due to its technological advantages, the laser is the predestined tool for manufacturing of high precision and demanding SMT and Wafer Stencils. This is because it impresses with the filigree realiziation of the finest geometries and packing densities as well as the process-related conical openings and steep cutting edges.