Perfect for high-frequency applications

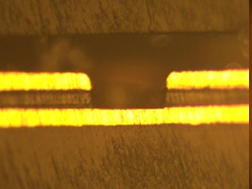

The laser structuring process is predestined for manufacturing for HF and microwave applications. In comparisons with etched printed boards, laser-structured printed boards came out on top in terms of precision, repeatability, and agreement with simulation results.

A welcome assistant in the electronics laboratory

The LPKF ProtoLasers are compact and undemanding. They only require a power outlet and compressed air and can fit through any lab door. The LPKF ProtoLasers S4 and U4 are each equipped with a vacuum table and a vision system and meet the requirements of laser class 1 in operation (no additional protective measures necessary).

Video: LPKF Copper Removal with ProtoLaser

For a large number of materials, suitable parameters for laser processing are already stored in a process library. This makes the ProtoLaser very easy to use. In addition, the user's own process parameters can be stored.

![[Translate to USA:] ProtoLaser R4 -- picosecond laser [Translate to USA:] ProtoLaser R4 -- picosecond laser](/fileadmin/mediafiles/_processed_/5/9/csm_ProtoLaser_R4_schraeg_NEU_cms__1a0ab3328c.png)