Applications

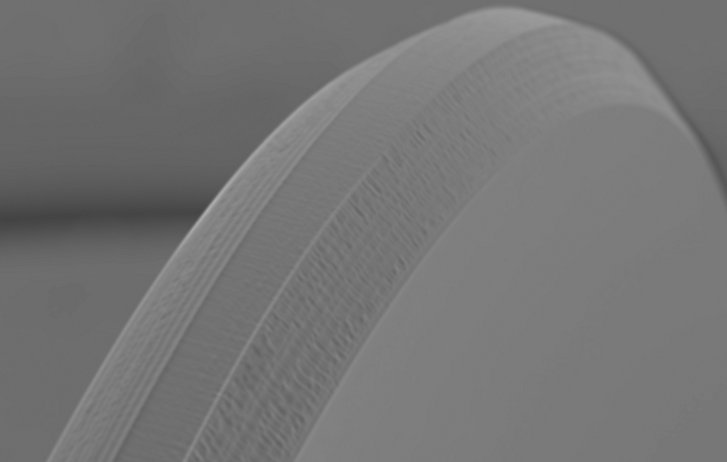

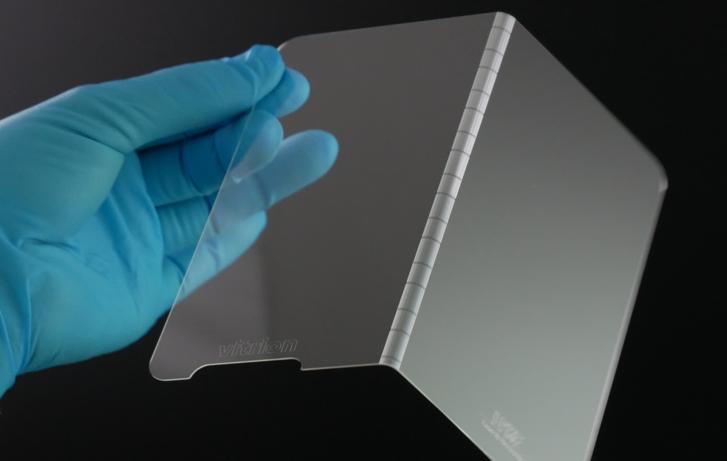

Break-proof edges for cover glasses

In contrast to conventional methods of cutting cover glass for mobile handheld device applications, the LIDE process provides absolutely crack- and break-proof edges. Almost any shape of holes and break-outs can be produced, even with the smallest radii. Complex grinding and polishing steps to reduce the risk of breakage are no longer necessary. The dimensional tolerances for the mounting of the glasses can be ensured without any further processing steps. This applies both to "pencil cuts" or "C cuts" and chamfer cuts.

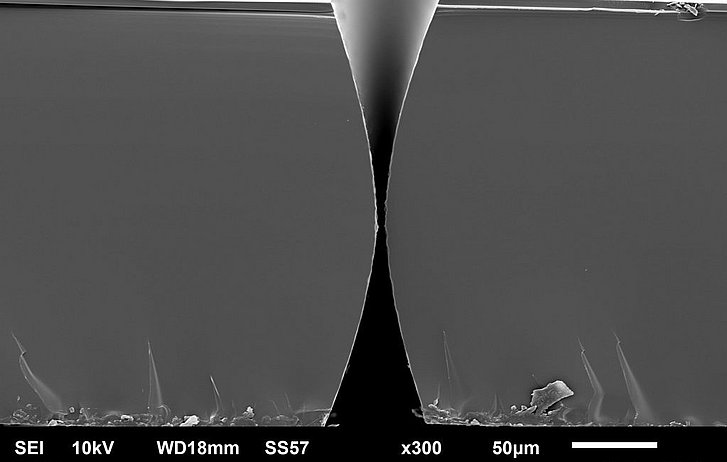

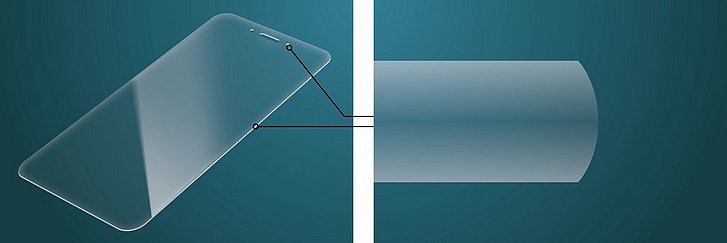

Production of foldable displays

With LIDE it is possible to make display glasses locally bendable by surface defect free micro cuts. This provides a solution for the use of glass in folding displays for smartphones and other mobile devices. The advantages of glass surfaces as an interface to the user can now also be applied to foldable displays. The LIDE laser system Vitrion CG 5000 impresses with its exceptionally high yield and productivity.

Key specifications at a glance

- Supported blank format: < 300 x 300 mm

- Glass thickness: 0.3 mm up to 1 mm

- Automated glass handling with customer-specific holders

- Prepared for integration into Manufacturing Execution Systems (MES)

- System dimensions (W x H x D): 1800 x 2000 x 3100 mm

Consulting and full-service support

Customers can rely on the LIDE expert and support team to assist in the development of new solutions and accelerate time to market.

The Vitrion brand stands for a full-service provider for LPKF's LIDE technology. The team supports you in every phase of your LIDE-based innovation. For more information on LIDE technology and application examples, please visit the website www.vitrion.com.

Please feel free to contact us at any time. We look forward to your questions.