Information

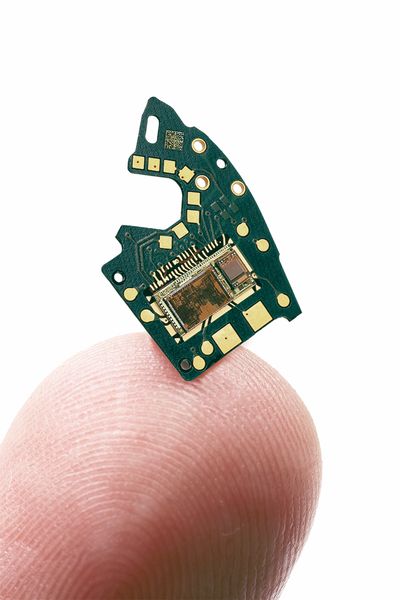

The UV laser system is ideal for cutting flexible, rigid-flexible and rigid printed circuit boards. Users benefit from the advantages of laser technology: the cuts are precisely positioned, there is a high degree of design freedom, and the surrounding material remains free of mechanical stress. The systems of the LPKF CuttingMaster series are easy to operate thanks to the sophisticated, integrated software. In addition, the compact machines offer a convincing price comparable to that of mechanical cutting systems - without compromising quality, efficiency or flexibility.

Process advantages through the use of lasers

- The laser process is fully software controlled. Changing materials or cutting contours are simply handled by adjusting the processing parameters and laser paths.

- Laser cutting with the laser does not cause any significant mechanical or thermal stress. The ablation products are extracted directly at the cutting channel. In this way even sensitive substrates can be precisely processed.

- The laser beam requires only a few µm as the cutting channel. In this way, more components can be placed on one panel.

Simple operation

- The LPKF CuttingMaster 2000 series makes depaneling a simple job: The layout files are easily transferred to the machine at the click of a mouse - without lengthy changeover times or previous time-consuming tool production.

Further information about Laser Depaneling

Technical Data

| Manual (P) | Automated (Ci) | |

|---|---|---|

| Max. Working Area (X x Y) | 350 mm x 350 mm | 350 mm x 250 mm |

| Positioning accuracy | +/- 25 µm | |

| Diameter of focussed laser beam | < 20 µm | |

| System dimensions (W x H x D) | 875 mm x 1510 mm (2070 mm)* x 1125 mm | |

| Weight | ca. 450 kg | |

*Height including status light

Available Variants

| Laser power | Wavelength | Pulse duration | 2000 series | CleanCut |

|---|---|---|---|---|

| 15 W | 355 nm (UV) | nano second | 2115 | - |

| 27 W | 355 nm (UV) | nano second | 2127 | X |

| 32 W | 532 nm (green) | nano second | 2232 | X |

Video

Images

Downloads

Brochure

LPKF CuttingMaster Systems (pdf - 581 KB)

![[Translate to USA:] Laser Depaneling with LPKF CuttingMaster](/fileadmin/mediafiles/_processed_/8/3/csm_Typo3_CM_2115_P_97a58c2442.png)