Micro Machining in the Lab

UV laser source as a versatile tool

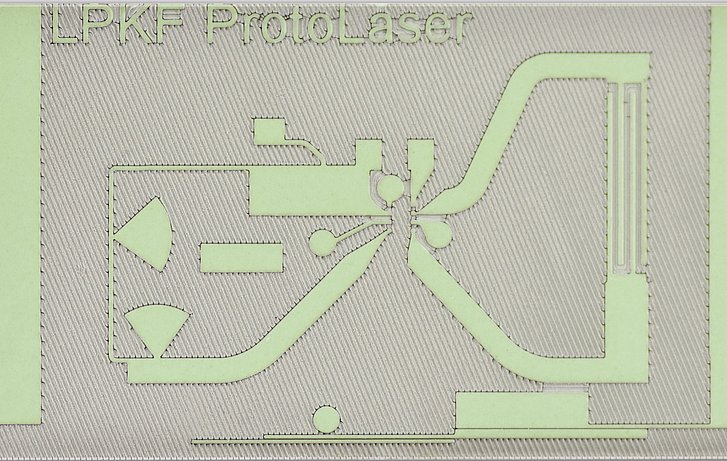

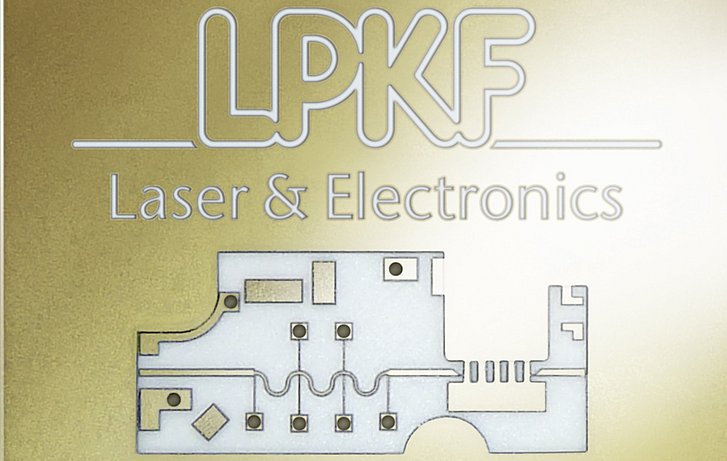

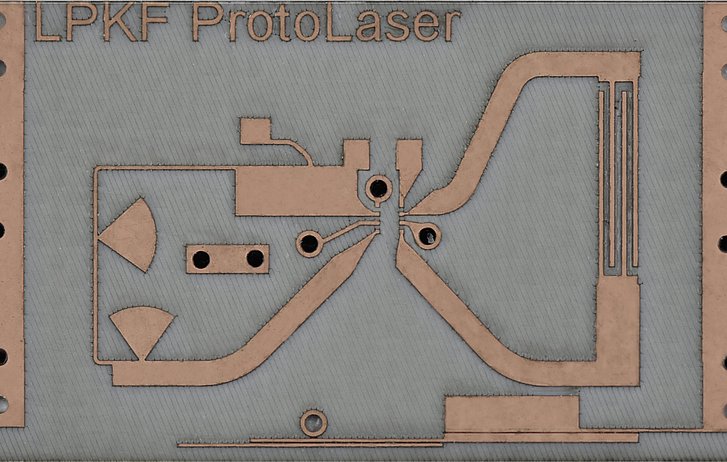

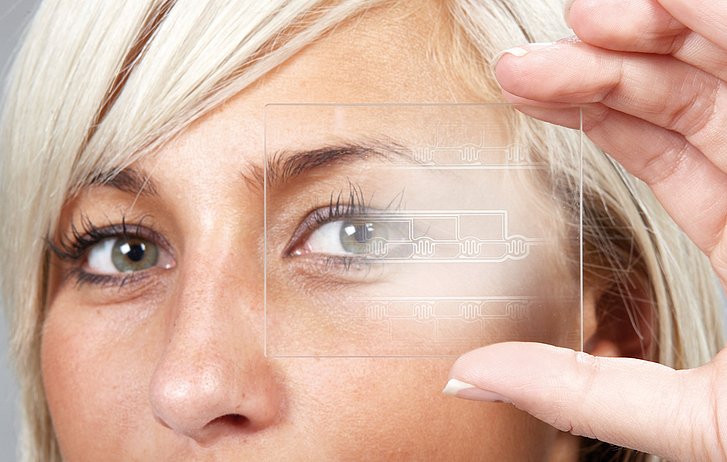

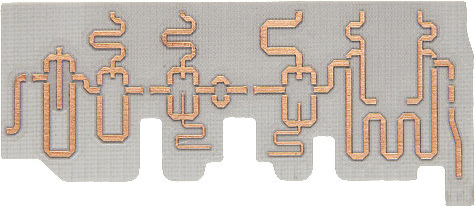

The LPKF ProtoLaser U4 uses a scanner-guided laser with a wavelength of 355 nm in the UV spectrum, that has been specially developed for use in electronics laboratories. This wavelength makes it possible for many material groups to be perfectly processed with the laser without additional tools, masks or films.

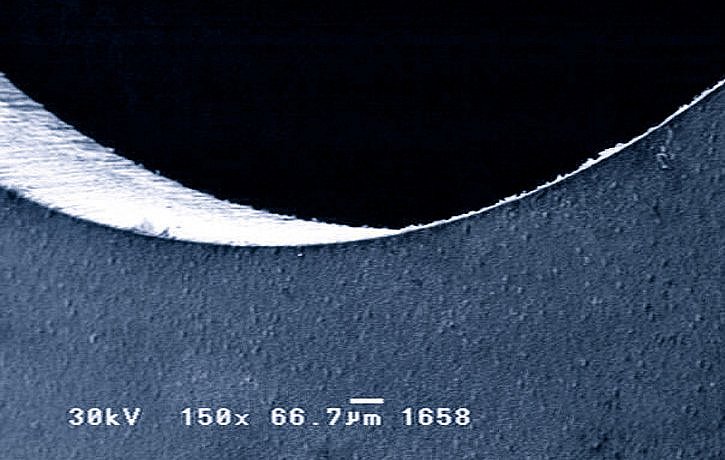

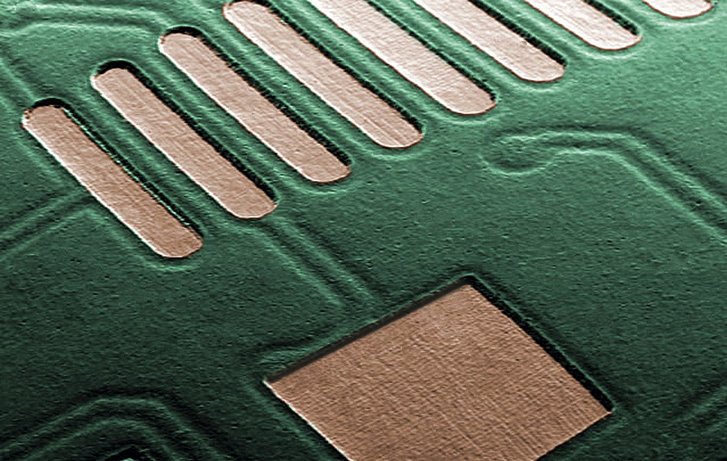

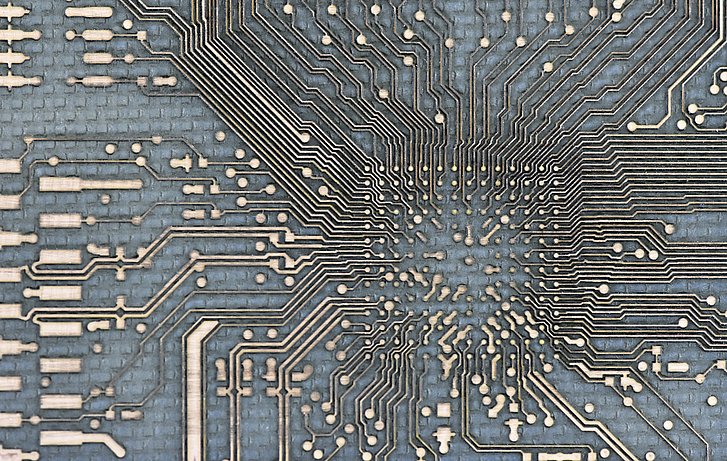

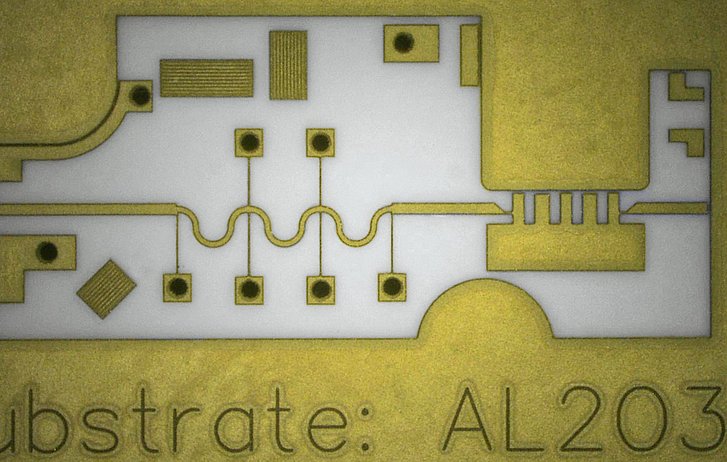

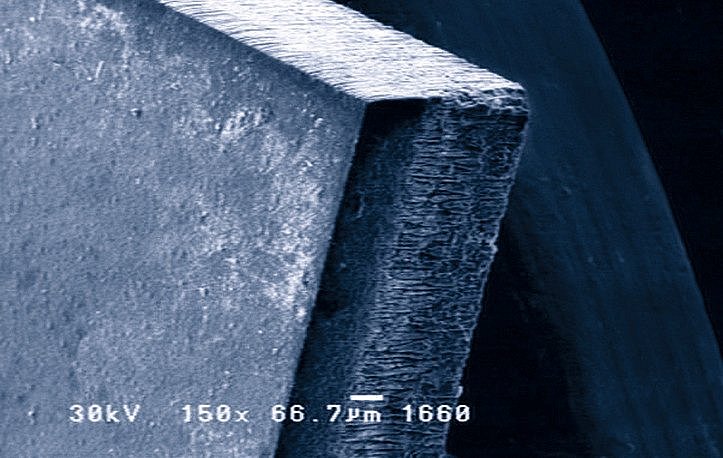

Placing scan fields next to each other results in a working range of up to 229 mm x 305 mm x 10 mm. The laser focus with a diameter of approx. 20 µm allows for structures with a pitch of 65 µm (50 µm line width, 15µm apart) related to FR4 with 18 µm Cu.

Powerful system software

The user-friendly LPKF CircuitPro PL system software gives access to all important process parameters. A comprehensive parameter library that not only includes many common but also exotic materials provides assistance for the operator's own projects.

Stabilization in the low-energy range

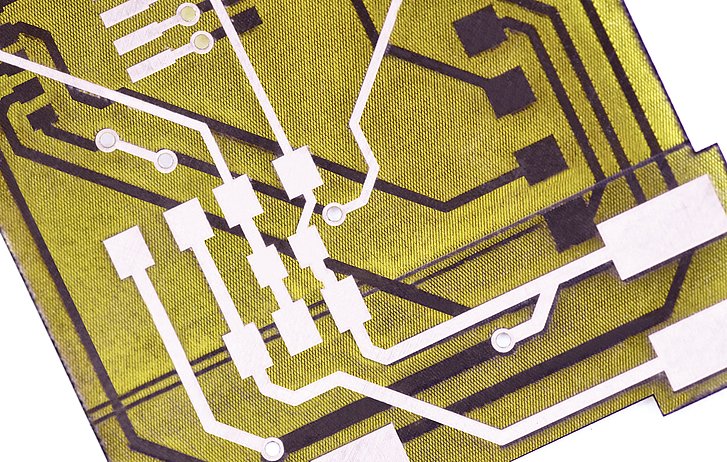

Fine, sensitive processes require very little laser energy. The new UV laser source is designed accordingly and is stable over a wide power range. This benefits applications with particularly thin layers or delicate materials.

Process Tracking

A power measuring field determines the actual power of the laser when in focus position. This results in accurate actual data for documenting the production process.

Vision system

The LPKF ProtoLaser U4 uses a newly designed, fast vision system optimized for laser micromachining. The camera and the image recognition process capture fiducials or geometric structures on the substrate to be processed.

![[Translate to USA:] LPKF ProtoLaser U4 [Translate to USA:] LPKF ProtoLaser U4 prototyping laser system](/fileadmin/mediafiles/_processed_/5/3/csm_Produkt_ProtoLaser_U4_4ae64bf5f9.png)

![[Translate to USA:] ProtoLaser R4 -- picosecond laser [Translate to USA:] ProtoLaser R4 -- picosecond laser](/fileadmin/mediafiles/_processed_/5/9/csm_ProtoLaser_R4_schraeg_NEU_cms__1a0ab3328c.png)